WHAT IS CARBON MONOXIDE?

- CO is a colorless, odorless, tasteless gas.

- It is a by-product of incomplete combustion (unburned fuel such as gas, oil, wood, etc.)

- Low concentrations of CO can go undetected and can contribute to ongoing, unidentified illnesses. At high concentrations, it can be deadly.

WHY IS IT DANGEROUS?

If there is CO in the air you breath, it will enter your blood system the same way oxygen does, through your lungs. The CO displaces the oxygen in your blood, depriving your body of oxygen. When the CO displaces enough oxygen, you suffocate.

WHAT ARE THE SYMPTOMS?

Continued exposure or high concentrations -

|

|

|

|

|

|

|

Long term exposure to low concentrations -

- Slight headaches

- Fatigue

- Shortness of breath with only moderate exertion

- Nausea

- Dizziness and confusion

WHY IS IT CALLED THE "GREAT IMMITATOR"?

- Symptoms of CO poisoning are very similar to the flu.

- Illness in your pets just preceding illness in a family member may suggest CO poisoning.

WHO IS AT GREATER RISK?

|

|

|

|

|

|

Note: Vulnerable people who are exposed even to low levels of CO for long time periods may have similar health affects as those exposed to high concentrations of CO.

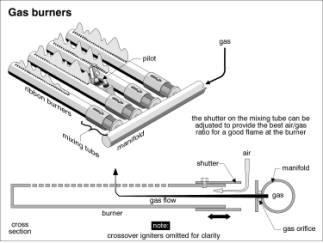

WHAT CAN PRODUCE CO IN OUR HOMES?

Anything that burns fuel or generates combustion gases including:

|

|

|

|

|

|

|

|

|

Solid fuels, such as wood, always produce carbon monoxide when they are burned. Gas and liquid fuels may produce no CO or very little.

WHAT ARE THE MOST COMMON SOURCES OF CARBON MONOXIDE?

1. Automobile exhaust in attached garages

This is responsible for 60% of all

CO alarms. People who warm their cars up in the garage are trapping CO inside

the garage. The CO can find its way into the home.

2. Gas cooking appliances

Reported to account for 20% of CO alarms.

May be a result of a misused, poorly

maintained, poorly installed, or unvented

cooking appliance.

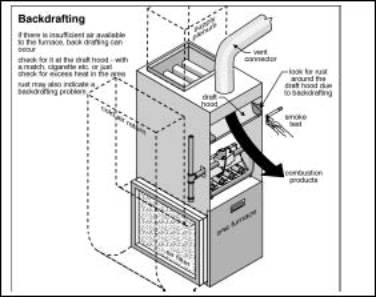

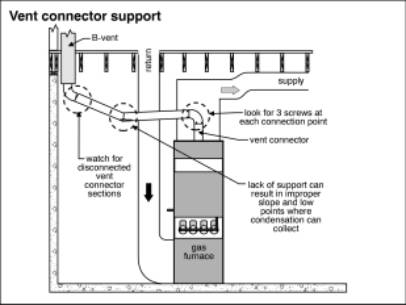

3.1 Poor draft/venting for fuel burning appliances -

appliances -

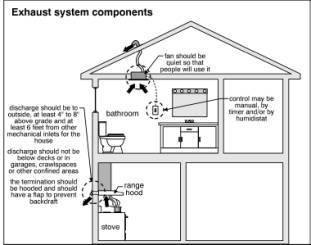

This is one of the most common and serious causes for CO build up and has been reported to account for up to 19% of CO alarms. The products of combustion are not being safely expelled to the exterior. This could be due to venting problems, such as blocked chimney flues or inadequate venting for appliances or fireplaces. Other problems include poor installation and negative air pressure in the house, causing backdrafting, often due to exhaust fans.

Other problems include:

3.2 Poor combustion at furnace

Inadequate combustion air to the furnace can result in incomplete combustion. If the furnace has a cracked heat exchanger, it is possible to get CO into the circulating air. It is also imperative that we do not deprive our heating equipment and fuel burning appliances of air; especially in air-tight homes where running exhaust fans can result in a shortage of combustion air. Combustion air is essential for safe operation of furnaces, water heaters, and other fuel burning equipment.

3.3 Leakage -

A leak in a chimney or flue pipe.

3.4 Ventilation -

Barbecues or gasoline powered equipment operating in a attached garage, basement,

or enclosed area.

Are there more problems with carbon monoxide today than 30 years ago?

Yes, due to -

- More energy-efficient, air-tight homes

- Less natural ventilation

How can I guard against carbon monoxide poisoning?

The first line of defense is to have your home heating systems, fuel burning appliances, flues and chimneys checked and/or cleaned annually.

Inspection checklist:

Specialists should check for:

- Blocked openings to flues and chimneys

- Cracked,rusted,or disconnected flue pipes

- Dirty filters

- Rusted or cracked heat exchangers

- Soot or creosote build-up inside fireplaces and chimney flues

- Exhaust or gas odors.

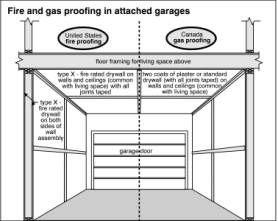

- Attached garages require gas proofing and automatic closers for doors into the home

- Adequate combustion air

- Adequate venting on indoor combustion appliances (i.e-gas stoves)

The second line of defense is a CO detector.

CO DETECTORS

Background

- New technology

- Introduced in the early 1990's

- Designed to warn homeowners when CO reaches dangerous levels within the home

How do they work?

- CO detectors sample the air at specific time intervals

- A microchip inside the detector stores the reading and keeps track of the level of CO that the detector is exposed to over time

Types of sensors:

Residential

- Biometric (Oldest type of sensor)

- Metal Oxide Semi-conductor

- Electrochemical (The best of the three types for a residential sensor)

Industrial

- Infrared -

Highly advanced, very expensive.

Not something you would find at Home Depot.

The detectors are supposed to sound an alarm when exposed to a set level of CO (measured in parts per million) over a specific time period. These levels or standards are set by UL (Underwriters Laboratories).

Old Standard (Units manufactured between October 1, 1995 and October 1, 1998)

First Generation CO detectors

Exposure |

CO (ppm) |

Time |

To a low level for a prolonged period of time |

15 |

Alarm after 30 days |

To a low level of CO for an extended period of time |

100 |

Alarm within 90 minutes |

To a moderate level of CO for a shorter period of time |

200 |

Alarm within 35 minutes |

To a high level of CO for a short period of time |

400 |

Alarm within 15 minutes |

New Standard (Units manufactured after October 1, 1998)

Exposure |

CO (ppm) |

Time |

To a low level for a prolonged period of time |

30 |

Alarm after 30 days |

To a low level of CO for an extended period of time |

70 |

Alarm within 189 minutes |

To a moderate level of CO for a shorter period of time |

150 |

Alarm within 50 minutes |

To a high level of CO for a short period of time |

400 |

Alarm within 15 minutes |

The UL Standard was revised and any detector manufactured after October 1, 1998

must conform to the new Standard.

Also included in the new Standard is:

- CO detector should ignore a CO level reading of 70 for at least 1 hour without alarming.

- CO detector should ignore a CO level reading of 150 for at least 10 minutes without alarming.

- Must only signal under alarm or trouble. No low-level warning signal is allowed.

- Must have a SILENCE button to shut it off. Must re-alarm after 6 minutes if CO levels persist.

- Must meet the specificity test referencing non-alarm status at specific concentrations of certain gases and vapors.

To put levels into perspective: Note: These studies are generally done on young, healthy people. These symptoms can change drastically depending on age, sex, weight, habits (e.g. smoking), and most importantly, your health.

CO Level (ppm) |

Health Effect |

0 |

Desirable level |

9 |

Maximum outdoor air quality level as per EPA |

50 |

Maximum concentration for a continuous exposure in an 8 |

hour time period (OSHA standard) |

|

400 |

Headaches in 1 to 2 hours, life threatening after 3 hours |

800 |

Nausea and convulsions, death within 2 hours |

1600 |

Nausea within 20 minutes, death within 1 hour |

12,800 |

Death within 1 to 3 minutes |

THE CONTROVERSY

• Reliability of the detectors.

THE ISSUE

- CO detectors are supposed to alarm at certain levels as indicated in the tables above.

- Recent testing suggests that many of these devices are not nearly as reliable as they should be.

- CBC has provided television coverage that focused on false alarms and the reliability of CO detectors.

EXAMPLE

- In 1994, Chicago was the first major city to make these detectors mandatory in the living space.

- In the last three months of 1994, the Chicago Fire Department responded to 8,600 CO alarms.

- In almost every case there was no dangerous level of CO found during follow-up investigations.

RESULT

- Laboratory testing was done

- Up to 1/3 of the alarms tested, failed to alarm.

REASONS

- TECHNOLOGY

- Technology for residential CO detectors is very primitive.

- Industrial detectors have a different set of standards and more sophisticated technology. As a result, they are very expensive.

- Different detectors have large variances on the levels at which they are supposed to alarm. The sensor technology used in home alarms is not designed to measure and display low level, short term concentrations of CO. Substantial differences exist in the sensitivity of different sensors at low levels. As a result, they may go off too soon or not soon enough.

- HUMIDITY

- Standards require these devices to be tested at a humidity of 50%.

- Testing revealed that many devices failed to respond when humidity levels were low even though they are supposed to work within a large humidity range. See your CO detectors manual.

- In Canada, humidity levels can fall well below 50% (in fact the humidity should not be higher than 40%) during the cold season when furnaces and other fuel burning appliances are in full operation.

- EFFECT OF OTHER GASES AND VAPOURS

- Other gases such as Carbon Dioxide can also trigger a CO alarm. The UL 2034 Standard requires that CO alarms do not alarm when certain concentrations of other gases and vapors. exist in the vicinity of a CO detector. The level for Carbon Dioxide in the old standard was low, which may have contributed to many false alarms with first generation CO detectors.

CONCLUSIONS

- CO detectors are designed to protect the average healthy human from death or serious injury under the current standards; however -

- People who are more susceptible cannot depend on these devices for total protection. In this case, more sensitive CO detecting equipment should be used.

- Several groups are working with UL to improve the standards. October 99 revisions have already been drafted.

- There is room for improvement by imposing stricter standards as well as technological development.

- It is critical that people understand the dangers of CO and that the people who investigate it are properly trained and are using CO testing equipment properly.

Where to install a CO detector?

- One or more CO detectors in accordance with the manufacturer's recommendations. Usually one per floor.

- Maintain and test regularly as instructed by the manufacturer.

Things to look for when buying a CO detector?

1) Type of sensor (electrochemical)

2) Certification-UL 2034

3) Conforms to new standard

4) IAS 6-96 is a supplementary standard to the UL 2034 which includes reliability testing. This standard may not be visible on the box.

5) Other considerations include digital display, sensor life, power source, and warranty.

How does all of this relate to your home inspection?

A home inspection may reveal a potential Carbon Monoxide source.

Common deficiencies found during inspections include:

- Venting deficiencies

- Damaged or rusted flue pipes

- Dirty or blocked chimney flues

- Cracked heat exchangers

- Gas proofing deficiencies

- Inadequate combustion air

- Poorly installed equipment

Limitations -

- Visual Inspection

- Equipment available

There are other ways to test CO levels in a home. These tests go beyond the scope of a standard home inspection.

No text or graphical material may be copied from this site without the express written permission of

Carson, Dunlop & Associates Ltd. Line drawings are from the Carson Dunlop Home Inspection Training Program

and Home Inspection Software Tool - Horizon